Filler Masterbatch For Woven Sacks

Generally apply for: Bags, big bags, lamination or coating of raffia bags, Cement sacks, agricultural protection and packaging, etc.

The Exclusive Filler Masterbatch Bespoke for your Raffia Solutions

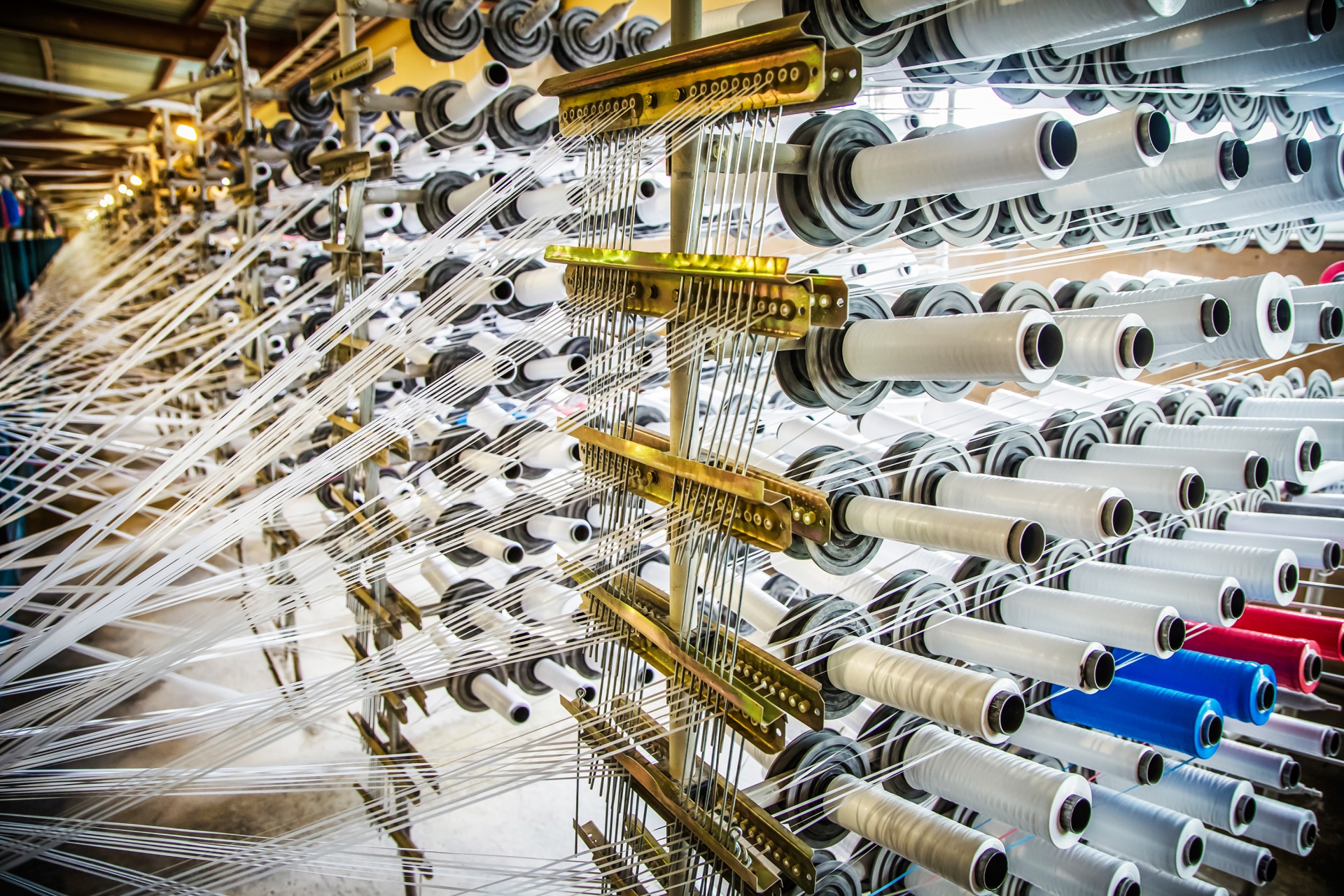

We take advantage of the elongation and tenacity properties in the different deniers offered in our range of grades, and then apply an orientation (stretching) and heat tempering process to obtain excellent quality raffia ribbons and bags.

Suggested Usage Rate

Woven Sacks Filler Masterbatch Granules

Compatibility: PE, HDPE, PP

Raffia or woven sacks is a packaging material made from weaving ribbons of polypropylene. Raffia is commonly used to produce industrial packaging, such as cement sacks, as well as agricultural protection and packaging. The polymers used for its manufacture are polyethylene (PE), mainly high-density (HDPE), and polypropylene (PP).

Check out our detail information of filler masterbatch for woven sacks/ raffia applications

Popular type

Cost savings, improve processing and output, prinitablity, General purpose for PP woven sack & FIBC PP Raffia with low denier and medium running speed (below 350 rpm)

Average type

Cost savings, good quality, General purpose for PP woven sack & FIBC PP Raffia with low denier and medium running speed (below 350 rpm), improve processing and output, prinitability, whitenss, gloss

High level type

General purpose for PP woven sack & FIBC PP Raffia with low denier & high running speed (400-500 rpm),highly suitable for high speed machine, strength and elongation, printability, super gloss & whiteness

Customizable Granules

Depend on the customer’s requirements, the compatibility, properties and characteristics will be determine

Packaging & Delivering

- 25 kgs per PE bag

- 1200kgs/jumbo bag

- Our Filler Masterbatch plastic granules are quite sensitive to be moisture

- Storing in original packing bags is acceptable

- Please pay attention to the due of using after open the packing bags, the most appropriate time is making to use immediately after opening the product bags.

- In the case, the products have some moisture problems, please dry them out by hot air recycle machine with degree around 90 Celsius degree into a half of an hour or you can give out 1% desiccant filler masterbatch before making to use