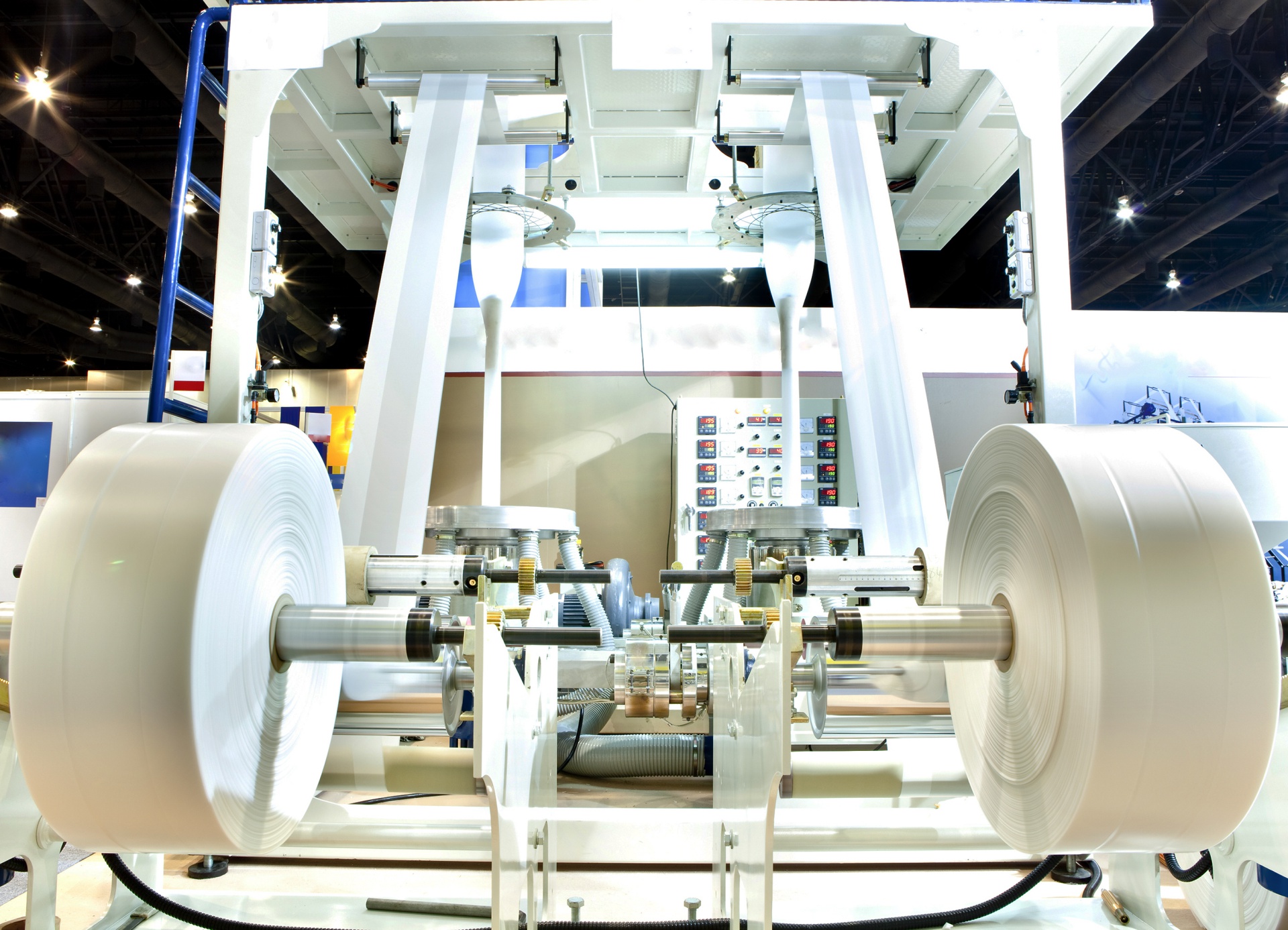

Filler Masterbatch for Blowing Film

Generally apply for plastic bags and sacks or in other in tube form like a sheet, shrick film, stretch film, container liners, bag films and in laminating film.

The Exclusive Filler Masterbatch Solution for Blowing Film Objects

Fillplas’s Filler Master Batch is produced in a highly respective environment, with the high-quality process and selective raw materials. Focus on satisfying customer’s plastic needs, our expertise shares a global database of successful matches, which we combine with unequaled polymer knowledge to provide you with accurate masterbatches and colored resins and compounds.

Suggested Usage Rate

Blowing Film Filler Masterbatch Granules

Compatibility: PP, PE, LLDPE, LDPE, HDPE

Filler Master Batch is compounded of high-quality filler, polymer resin and other additive agents by twin-screw machine. It is widely used in the plastic industry, including blowing film, to reduce the production cost and improve the character of final products.

The grade types and description of filler masterbatch granules for blowing film.

Popular type

We provide customers with a variety of grades of filler masterbatches which are well-known as economy grades. These grades have good dispersion, high toughness, improve elongation, more whiteness and reduce the cost of the end product. Products of these grades can improve processing and output, printability and whiteness and gloss. In particular, they can help customers to reduce production expense and save the cost of the end product significantly.

Average type

We provide customers with a variety of grades of filler masterbatches that not only can enhance the character of the product, but also reduce expense and save cost at the same time. These grades have good dispersion, high toughness, improve elongation, more whiteness, gloss and printability.

High level type

We can provide customers with high-quality filler masterbatches, which not only can enhance the character of the product but also reduce expense and save cost at the same time.

In Fillplas, we produce a number of grades that are highly suitable for HD film and quality thin film. They help improve significantly not only processing and output but also stiffness, strength, gloss, and elongation. While this grade enhances sealing & printing, TiO2 content in the ingredient of our filler masterbatches helps to increase the whiteness of the end product.

Customizable Granules

Depend on the customer’s requirements, the compatibility, properties and characteristics will be determine

Packaging & Delivering

- 25 kgs per PE bag

- 1200kgs/jumbo bag

- Our Filler Masterbatch plastic granules are quite sensitive to be moisture

- Storing in original packing bags is acceptable

- Please pay attention to the due of using after open the packing bags, the most appropriate time is making to use immediately after opening the product bags.

- In the case, the products have some moisture problems, please dry them out by hot air recycle machine with degree around 90 Celsius degree into a half of an hour or you can give out 1% desiccant filler masterbatch before making to use