The Ultimately Spectrum Laboratory Experiment and R&D

BESPOKE SOLUTIONS

Understanding the insight of clients in the plastic raw material industry, we design a whole spectrum R&D in testing in order to provide the custom-made sample that bespoke each of your inquiries of properties, masterbatch size, and other special characteristics

Filler Masterbatch Laboratory Testing

Our laboratory testing includes but not limited to 7 based steps following:

1

1Step 1

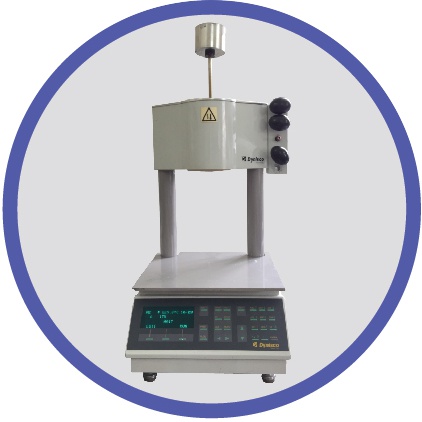

MI Flow Coefficient Measurement

Testing standard:

ASTM D1238

190 Celsius degree/ 2.16 kg

2

2Step 2

Moisture Measurement

Testing standard:

OHAUS-MB45

105 Celsius degree/ 20 mins

3

3Step 3

Particle Size Distribution of Limestone Fillers Measurement

Testing standard:

MASTERSIZER 3000E

In ethanol/ water environment

4

4Step 4

Whiteness Color Measurement

Testing standard:

CIE 1982

L: Brightness – Darkness

A: Red – Green

B: Yellow - Blue

6

6Step 6

Film Thickness Measurement

Testing standard:

Mitutoyo No. 2046S

10µm = 0.01mm

Below 1cm

5

5Step 5

Film Coating Measurement

Testing standard:

CO.FO.ME.GRA/DTP 642

7

7Step 7

Viscosity Measurement

Testing standard:

LVDV-E,BROOKFIELD-USD