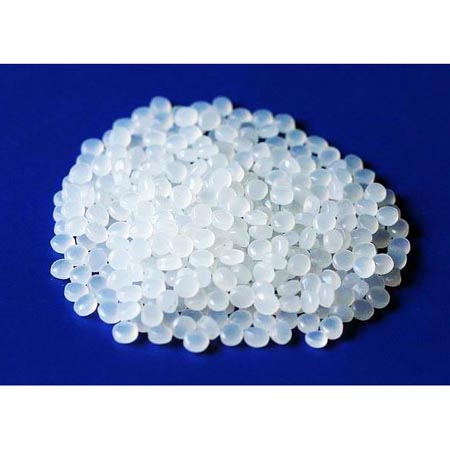

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer. It is used in a variety of applications to include packaging for consumer products, plastic parts for various industries including the automotive industry, special devices like living hinges, and textiles.

Types of polypropylene

There are two main types of PP available: homopolymers and copolymers.

PP homopolymer is the most widely utilized general-purpose grade. It contains only propylene monomer in a semi-crystalline solid form. Main applications include packaging, textiles, healthcare, pipes, automotive and electrical applications.

PP copolymer family is further divided into random copolymers and block copolymers produced by polymerizing of propane and ethane.

Advantages of polypropylene

- Being readily available and relatively inexpensive.

- Having high flexural strength due to its semi-crystalline nature.

- Having a relatively slippery surface.

- Being very resistant to absorbing moisture.

- Having good chemical resistance over a wide range of bases and acids.

- Possessing good fatigue resistance.

- Having good impact strength.

- Being a good electrical insulator.

Disadvantages of polypropylene

- Having a high thermal expansion coefficient which limits its high-temperature applications.

- Being susceptible to UV degradation.

- Being known to be difficult to paint as it has poor bonding properties.

- Having poor resistance to chlorinated solvents and aromatics.

- Being highly flammable.

- Being susceptible to oxidation.

Interesting material properties of polypropylene

- The melting point of polypropylene – The melting point of polypropylene occurs at a range.

Homopolymer: 160 – 165°C

Copolymer: 135 – 159°C - The density of polypropylene – PP is one of the lightest polymers among all commodity plastics. This feature makes it a suitable option for lightweight/weight saving applications.

Homopolymer: 0.904 – 0.908 g/cm3

Random Copolymer: 0.904 – 0.908 g/cm3

Impact Copolymer: 0.898 – 0.900 g/cm3 - PP chemical resistance

Excellent resistance to dilute and concentrated acids, alcohols and bases

Good resistance to aldehydes, esters, aliphatic hydrocarbons, ketones

Limited resistance to aromatic and halogenated hydrocarbons and oxidizing agents. - Flammability: Polypropylene is a highly flammable material.

- PP retains mechanical & electrical properties at elevated temperatures, in humid conditions and when submerged in water. It is water-repellent plastic.

- PP has good resistance to environmental stress cracking.

- It is sensitive to microbial attacks, such as bacteria and mold.

- It exhibits good resistance to steam sterilization.

Fillplas has a range of PP filler masterbatch which is a material mixed of CaCO3, PP resin, and other additives. And they use this PP filler in many PP plastic product applications. You could visit our website to have more information.