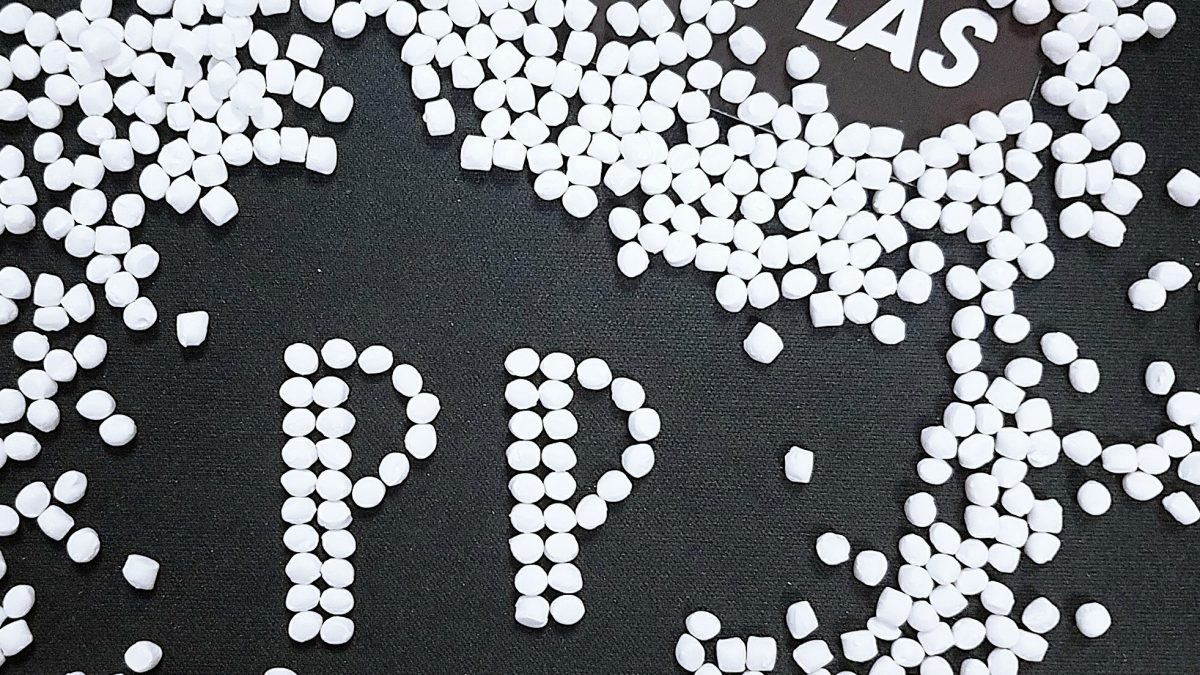

PP filler masterbatch is one range of CaCO3 filler masterbatch. Then it is widely used in many applications of producing plastic products.

PP filler masterbatch for PP raffia

PP filler masterbatch is conventionally used in PP woven bags, weaving tapes, or bands to offer anti-splitting and anti-fibrillation effects.

This PP filler gives the following benefits to products:

- CaCO3 provides faster heat transfer and the needed energy to heat up or cool down the mixture lower.

- Reduced anti fibrillation (anti split agent).

- Increased tape stiffness.

- Increase opacity.

- Cost benefits due to the difference in price between filler & resins.

The conventional loading rate of CaCO3 filler masterbatch is in a range of 2% to 35% in final articles.

PP filler masterbatch for non-woven fabric

This material is used in different plastic sectors:

- Packaging: non-woven shopping bags.

- Hygiene: baby and adult diapers; female hygiene.

- Medical: protective clothing

- Technical products: architectural nonwovens; coating substrates; agro textiles & geotextiles; filtration; disk covers; wipes.

The recommended usage of 5~40% depends on the final product requirements.

PP filler masterbatch for injection molding

The use of PP filler in injection molding products is a proven solution that has the ability to improve product quality and productivity. It is widely used in furniture, household items, automobile details.

The loading rate of 5to 30% depends on the final product requirements.

PP filler masterbatch for PP thermoformed sheet

Filling polypropylene with up to 60% calcium carbonate is a proven solution for running polypropylene on existing polystyrene thermoforming machinery with comparable line performance and end-product quality.

Thermoformed sheet products include:

- Disposable cups, plates.

- Food trays, pots, and covers.

- Plant pots and seeding trays.

- Profiled the building products.

- Household items.

- Automatic interior trim articles

The recommended usage rate at 15~35% depends on the final product requirements.

PP filler masterbatch for PP pipes

The use of calcium carbonate filler masterbatch in polyolefin pipes production technology will give pipes higher hardness. Furthermore, it also improves processing ability, reduces cooling time, and reduces costs. In accessories manufacturing, it helps reduce cooling time significantly and increase profit margins.

PP filler masterbatch is one of FillPlas’ main products, and you could visit our website to have more information.