Calcium carbonate is a chemical compound with the chemical formula CaCO3. It is a common substance found in rock in all parts of the world and is the main component of filler masterbatch.

Calcium carbonate fillers can be differentiated as ground natural carbonate (GCC) vs precipitated carbonate (PCC).

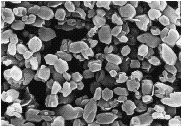

Ground natural carbonates (GCC) are further characterized as dry-ground products, usually in grades from 200 mesh to 325 mesh, and wet-ground products. Of the wet-ground products, fine ground (FG) calcium carbonates range from about 3 to 12 micrometers in median esd, with a 44 micrometer top size. Ultrafine ground (UFG) grades range from about 0.7 to 2 micrometers in median esd, with a 10 micrometer top size.

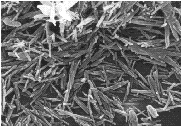

Ground calcium carbonate is most often available with rhombohedral or prismatic particles. Needle-like calcium carbonate is collected as aragonitic sands in the Carribean, but this is not generally used as filler other than in cement.

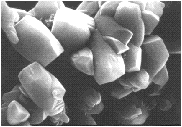

Precipitated calcium carbonate (PCC) is produced for applications requiring any combination of higher brightness, smaller particle size, greater surface area, lower abrasivity, and higher purity than is generally available from ground natural products.

Fine PCC has typically a 0.7-micrometer median, while ultrafine PCC has typically a 0.07-micrometer median. The shape of PCC crystals can be manipulated according to end-user requirements.

Both GCC and PCC are available with stearate surface treatments for better compatibility with polymer matrices. With FILLPLAS, we usually utilize GCC (Ground Calcium Carbonate).

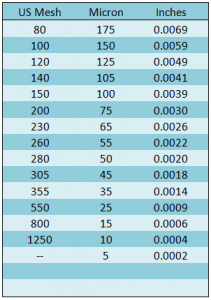

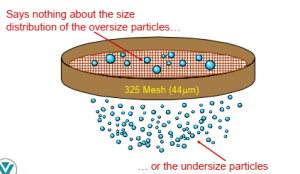

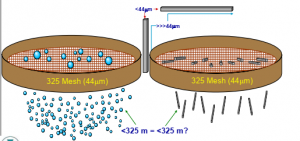

In terms of a size measurement, Calcium Carbonate filler is graded by Mesh Size. So, What is Mesh Size?

Mesh material is often used in determining the particle size distribution of a granular material. For example, a sample of filler masterbatch may be placed atop a mesh with 5 mm openings. When the mesh is shaken, grains that under standard and dust pass through the mesh while whole qualified ones are retained on the mesh.

This type of test is common in some industries, and to facilitate uniform testing methods, several standardized mesh series has been established. Applicable standards are ISO 565 (1987), ISO 3310 (1999), ASTM E 11-70 (1995), DIN 4188 (1977), BS 410 (1986) and AFNOR NFX11-501 (1987).

With Mesh Size data, we have also Particle Size – The percentages by weight or number of each fraction into which a powder sample has been classified with respect to sieve number. he most commonly used metrics when describing particle size distributions are D-Values ( D50 & D97) which are the intercepts for 50% and 97% of the cumulative mass, that’s why we have converted the table from mesh to micron (µm) below:

|

|

D-values can be thought of as the diameter of the sphere which divides the sample’s mass into a specified percentage when the particles are arranged in an ascending mass basis. The D50 is the diameter at which 50% of the sample’s mass is comprised of particles with a diameter less than this value. D50= 3 means 50% < 3 µm and 50%>3 µm The D97 is the diameter of the particle that 97% of a sample’s mass is smaller than and 3% of a sample’s mass is larger than. D97= 15 means 97% < 15 µm and 3%>15 µm

MASTER SIZE MS3000- SMARTER PARTICLE SIZING |

FILLPLAS mainly uses the D97 = 8/ 10/ 15 product line for our filler.