Definition of blown film

Blown film is a manufacturing process that produces films of plastic sheeting and tubes. These sheets or tubes can either be fully cylindrical or have other objects inserted into them so they form useful objects like shopping bags, rubbish bags, or cling wrap.

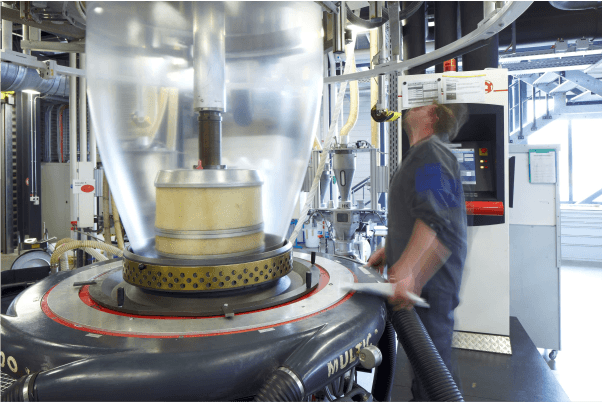

The process of blown film

The process of the blowing film is reasonably simple. Firstly, we must take plastic pellets and heat them to their melting point. Then we force the plastic through a cylindrical die and forms a thin-walled bubble. The next step, the bubble, and this bubble are fed up through a scaffold where the tube continues to rise. Over this length, the plastic begins to cool. Once it has cooled enough, it collapses down on itself, forming a flattened tube. This tube is passed through various rollers and spun onto a spool. The edges of the tube can be trimmed and it can also be punched, cut, or printed on before going on the spool.

Usage of blown film

We use the blown film process to produce a wide variety of products, ranging from simple monolayer films for bags to very complex multilayer structures used in food packaging. Blowing film coextrusion can make multilayer film structures and these structures combine two or more molten polymer layers.

The blowing film can produce up to 130 meters of products in a single minute. The sheets and film they can produce can be as fine as 10-20 microns (0.01mm – 0.02mm) to 250 microns (0.25mm) thick.

Most blown film is either High or Low-Density Polyethylene (HDPE or LDPE). Moreover, other polymers that can be processed by blown film extrusion are polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), ethylene-vinyl acetate (EVA), ethylene vinyl alcohol (EVOH), polyamide (PA), and polyurethane (PU). Markets that blown film extrusion serves are as follows:

- Industrial films and bags

- agricultural and construction films

- barrier films

- stretch films

- PVC cling films

- laminating films

- can liners

- high barrier small tube systems

Fillplas product is popular in blowing film application and you could visit our Fillplas website to get more details.