General

Several design of packaging options and features are available. Some bags have gussets to allow a higher volume of contents, special stand-up pouches have the ability to stand up on a shelf or a refrigerator, and some have easy-opening or re-closable options. Handles are cut into or added into some.

Bags can be made with a variety of plastics films. Polyethylene (LDPE, LLDPE, etc.) is the most common. Other forms, including laminates and co-extrusions can be used when the physical properties are needed. Plastics to create single use bags are primarily made with Fossil fuels.

Plastic packaging bags usually use less material than comparable to boxes, cartons, or jars, thus are often considered as “reduced or minimized packaging”. In June 2009 Germany’s Institute for Energy and Environmental Research concluded that oil-based plastics, especially if recycled, have a better life-cycle analysis than compostable plastics. They added that “The current bags made from bioplastics have less favourable environmental impact profiles than the other materials examined” and that this is due to the process of raw-material production.

Purpose of use

Depending on the construction, plastic bags can be suited for plastic recycling. They can be incinerated in appropriate facilities for waste-to-energy conversion. They are stable and benign in sanitary landfills. If disposed of improperly, however, plastic bags can create unsightly litter and harm some types of wildlife. Plastic bags have low recycling rates due to lack of separation ability. Mixed material recycling causes contamination of the material. However, plastic bags are reused before discard at a rate of 1.6 times.

Bags are also made with carrying handles, hanging holes, tape attachments, or security features. Some bags have provisions for easy and controlled opening. Reclosable features, including press-to-seal zipper strips, are common for kitchen bags bought empty and for some foods. Some bags are sealed for tamper-evident capability, including some where the press-to-reseal feature becomes accessible only when a perforated outer seal is torn away.

Boil-in-bags are often used for sealed frozen foods, sometimes complete entrees. The bags are usually tough heat-sealed nylon or polyester to withstand the temperatures of boiling water. Some bags are porous or perforated to allow the hot water to contact the food: rice, noodles, etc. Grocery stores are the single largest supplier of single use plastic bags.

Bag-in-box packaging is often used for liquids such as box wine and institutional sizes of other liquids.

Types of Plastic Packaging

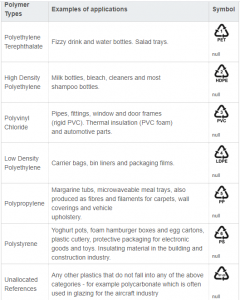

There are a number of different types of plastic packaging that require different treatment, reprocessing methods, and types of collection.

The following table illustrates the most common types of plastics used, their applications and the symbol which is often used to identify them on forms of plastic packaging.

Please contact us at info@fillplas.com