As following Common ways of packaging in plastic sector (Part 1)

Plastics Packaging

Plastics Packaging is used for packaging a variety of items i.e. fragile or non-perishable products; materials are used to cover the plastic related materials or products; Most companies recycle waste or scrap plastic for re-use in their own facilities, and even offer alternatives.

Without packing, these sophisticated goods with low shelf life will easily affect with climatic conditions and eventually result in their malfunction or destruction. This packaging is in such a way that no air or dust can sneak in and affect the goods.

Trends in Plastics Packaging

Changing consumer habits

• Increased urbanization and growing young population

• Increased use of home and personal care products

• Developments in the field of polymer science

• Increased investment in food processing and production in China

• Increased preference of plastic pouches, by consumers and retailers

Types of plastics packaging

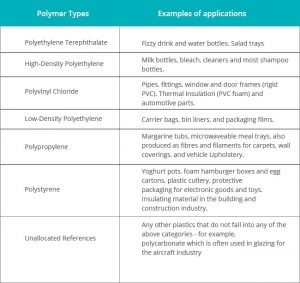

The most common types of plastics used and their applications are illustrated in the following table:

Benefits of Plastics Packaging:

Here are the benefits of choosing plastics packaging:

- Lightweight

• Durable

• Sustainable

• Cost-effective

• Versatile

Flexible Packaging

Flexible packaging can make with flexible materials that can packed, sealed and can retain the freshness of its content. Be it moulding the packages into a variety of shapes or preserving the flavor and safety of food or logistical aspects, all are covered under the flexible packaging.

This is the major benefit that makes flexible packaging the first choice for food packaging. The package can last for a very long time; if it stores in the right conditions. Flexible packaging is environmentally friendly as it uses less material and less wastages to make it.

Why Flexible Packaging?

Flexible Packaging can define as any package whose shape can be readily changed. Choosing the flexible packaging.

1.Adds value and marketability to food and non-food products alike from ensuring food safety and extended shelf life by providing heat seal, barrier protection, ease of use, press-to-seal and high-quality print finishes.

2.This type of packaging produces a fraction of waste during the printing process, overall reducing landfill discards.

3.Improvements in productions processes have reduced water and energy consumption, greenhouse gas and emissions and volatile organic compounds.

4.Finally, lighter-weight flexible packages result in less transportation-related energy and fossil fuel consumption, and environmental pollution.

Choosing these methods will provide the ideal results for your products. Keeping abreast of these packaging methods will give your products better shelf life and a competitive edge in the market. Many companies are using these methods to create awareness among their customers and help them in increasing their sales. Adopting these packaging methods can draw attention to latest trends to attract the consumers. Innovative packaging designs can also maximize the profitability of the product.

Filler masterbatch for Packaging

Filler Masterbatch is the main product of Fillplas. It can be said that masterbatch is a significant step that opened a new era for the plastic industry. Why? It is the best solution manufacturers use to improve the performance of raw plastic. Taical particles contribute to solving the problem of headache for manufacturers, which is to reduce production costs.

Filler Masterbatch is compounded of high quality filler, resin polymer and other additive agents by twin-screw machine. It is widely used in the plastic industry for applications such as blow film, blow molding, injection molding, wire drawing, bag molding, slip casting, dyeing, extrusion molding to reduce manufacturing charge and improve the character of final products.

Filler Masterbatch is an increasingly current used material in the plastic industry. Filler can be made from various types of fillers such as TALC, Na2SO4, BaSO4, fiberglass, etc but most commonly is CaCO3.

CaCo3 is a type of filler with a large volume and quite cheap, which makes it very popular. Normally CACO3 is used as Ground Calcium Carbornate (GCC) type with size from 1 to 3 microns (D50). The shape of stone powder greatly affects the processing and quality of taical. In particular, the more angular the shape, the greater the surface area, the more plastic bearing is needed, thus reducing the rate of usable stone powder. The shape of many angles makes the product heterogeneous, difficult to disperse, poorly distributed compared to spherical, cubic stone powder.ư

For packaging, we mainly make PE filler masterbatch for film bag, shopping bag, garbage bag,…

Contact us for more detail at info@fillplas.com