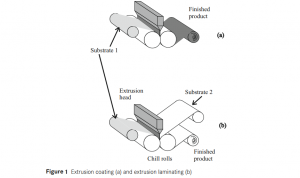

Extrusion coating and extrusion laminating operations are similar in the description because the process equipment for accomplishing them is essentially the same. Extrusion coating is the operation which a coating of a thermoplastic material applies to a substrate web, such as paper.

In extrusion lamination, a second web incorporates. Both webs combine with the adhesive action of the extruded thermoplastic material.

The processes depict in Fig. 1. In operations for converting packaging material. These two processes often combine in the same line to create a web such as:

paper/acid copolymer/foil/heat sealant layer.

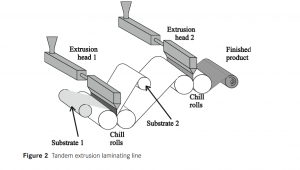

In the first operation, the paper and the foil are extrusion laminating using an acid copolymer as the adhesive. Next, the sealant layer applies as an extrusion coating. The operation can accomplish in two passes. Or in a single pass in a tandem extrusion line as shown in Fig.2. In such a line, both extrusion heads are usually capable of co-extrusion, as well.

LAMINATION

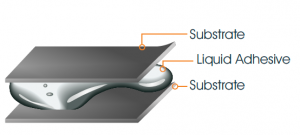

Laminating involves bonding two or more strips of a flexible backing material using an adhesive dissolved in a solvent .If an adhesive tape is used then the process is called complexing. These strips may make of film, paper or aluminium foil. The adhesive applies to the least absorbent strip. Which is then bonded to the second strip by the high pressure exerted by cylinders (heated if necessary). In order to produce an ultra strong lamination. This lamination may comprise two layers (duplex), three layers (triplex), or more.

Lamination techniques improve the appearance and properties of the backing materials. The end use of the product primarily dictate the type of adhesive selected . Various technologies can implement, such as laminating by calendaring, flat laminating,Hotmelt laminating,… to cover as many applications as possible.

COATING

Coating is a surface treatment which involves applying a liquid coating (adhesive, lacquer, paint, oil, etc.) to a backing material (paper, fabric, plastic film, metal foil, etc.) to give it specific beneficial properties for a specific application.

The coating process is usually following with drying and, if necessary, by cross-linking.

To understand the process of extrusion coating and laminating, it is necessary to start with the process in its simplest form, which, by the way, is how it is still practicing today by some converters.

FILLPLAS is developing the specialized grade of Filler Masterbatch for Extrusion products, as well as extrusion coating, laminating with the resins including PE and PP.