General film

Keep talking about the plastic film, another reason why it is somewhat difficult to get a grasp on plastic film is that it is used in such a wide range of products and packages. Typically, its usage is divided into two general categories—packaging and nonpackaging—that can also be broken down into smaller components. For example, there are three types of packaging applications in which film is used: food, nonfood and others.

It is important to keep in mind that within each of these categories, plastic film can vary by resin and color; it also may be made of one layer of plastic or as many as ten layers depending on the complexity of the package. Also, other materials—such as aluminum or paper—may be used in combination with plastic film to impart special properties. Therefore, even the following categories of the film are themselves made up of many diverse types of film.

Food Packaging

Food packaging film is used in such things as in-store bags for produce (such as apples and potatoes); all nonfrozen baked goods (such as rolls and breads); bakery bread and bun bags; tray covers for institutional deliveries of bakery products; bags-in-a-box (film used to contain fluid in a supportive box, such as boxed wine); boil-in-bags (film used to contain food prepared by keeping it in the package and placing it in boiling water); candy and confection bags and wrappers; carton liners (for such products as cake mixes); and meat, poultry and seafood wraps (such as hot dog and bacon film). As mentioned in the section on film generation, the only data available on the use of film in food packaging applications are restricted to the polyethylene family, even though other resins are used in food packaging as well.

Food packaging film is used in such things as in-store bags for produce (such as apples and potatoes); all nonfrozen baked goods (such as rolls and breads); bakery bread and bun bags; tray covers for institutional deliveries of bakery products; bags-in-a-box (film used to contain fluid in a supportive box, such as boxed wine); boil-in-bags (film used to contain food prepared by keeping it in the package and placing it in boiling water); candy and confection bags and wrappers; carton liners (for such products as cake mixes); and meat, poultry and seafood wraps (such as hot dog and bacon film). As mentioned in the section on film generation, the only data available on the use of film in food packaging applications are restricted to the polyethylene family, even though other resins are used in food packaging as well.

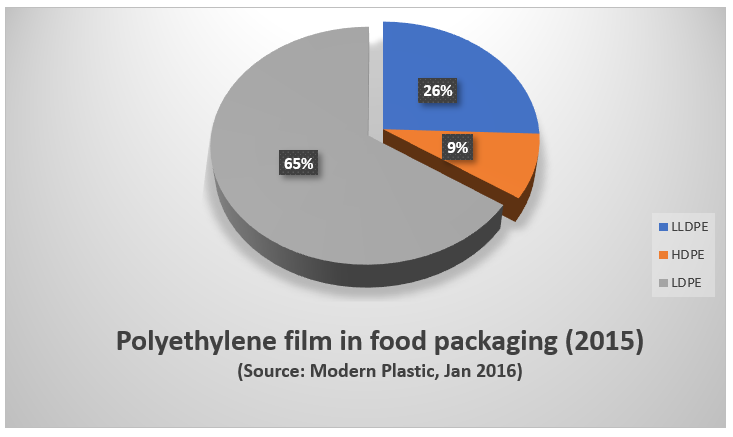

It is worth pointing out that LDPE is the polyethylene resin used most often in food packaging; it accounts for 65.5 percent of the total, with LLDPE making up 25.6 percent and HDPE making up 8.9 percent (see the following pie chart number 1).

Non-food Packaging

Nonfood packaging film refers to such things as industrial liners (film used to line supported structures such as Gaylord boxes, frozen pork box liners and liners for shipments of nuts and bolts), shipping sacks (film used to protect and/or contain contents such as bark and mulch bags), bubble packing, envelopes, multiwall sack liners, overwrap, and rack and counter bags. Again, data on film used in nonfood packaging applications are confined to the polyethylene family.

Nonfood packaging film refers to such things as industrial liners (film used to line supported structures such as Gaylord boxes, frozen pork box liners and liners for shipments of nuts and bolts), shipping sacks (film used to protect and/or contain contents such as bark and mulch bags), bubble packing, envelopes, multiwall sack liners, overwrap, and rack and counter bags. Again, data on film used in nonfood packaging applications are confined to the polyethylene family.

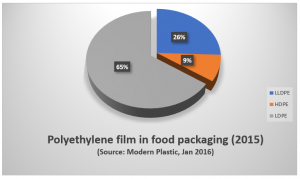

As Pie chart number 2 shows, LDPE is the polyethylene resin used most frequently in nonfood packaging applications. It composes 54.9 percent of the polyethylene used in nonfood packaging. Whereas LLDPE composes 35.5 percent and HDPE composes 9.6 percent.

Other Packaging 1

The other types of packaging in which film is found are stretch and shrink wrap. Stretch wrap is a strong, highly flexible film that can be stretched to take the shape of a product or products. It is used in a variety of applications ranging from overwrapping fresh meats to securing shipping cartons to pallets. Stretch wrap usually is made of co-extruded LLDPE and LDPE, although it can be made from individual plastic resins, such as LLDPE, LDPE and PVC.

Shrink wrap, on the other hand, is a plastic film that is applied loosely around products, sealed by heating the seams and shrunk through a heating process to take the shape of the products. In shipping, it can be used to bind multiple packages of less than pallet size together (such as five 20-ounce cans of beans or three juice boxes). Or used over an entire pallet of packages. About these applications, shrink wrap typically is made of LDPE, although it can be made from other resins as well, such as LLDPE and PP. Addition to shipping applications, shrink wrap also can be used for bundling purposes, such as bundling magazines and papers. And it can be used to protect and display such products as albums and compact disks.

Other Packaging 2

There are several ways to tell stretch wrap and shrink wrap apart: stretch wrap usually feels somewhat tacky to the touch and is very flexible. Whereas shrink wrap may be more brittle (or crinkly) to the touch and does not stretch when pulled. In addition, stretch wrap usually is wrapped around products, whereas shrink wrap will enclose the product (that is, have a top and bottom cover). Which makes it an attractive choice for shipping products in extreme weather conditions or for products that need extra protection.

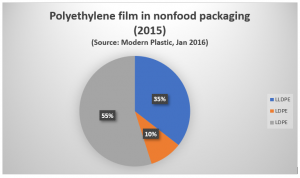

Data compiled by Modern Plastics show that a total of 1,074 million pounds of polyethylene film were used in “other” packaging applications in 2015. (Again, data are not available for nonpolyethylene resins or for HDPE.) As piechart number 3 shows, LLDPE is used most often in stretch wrap applications (at 802 million pounds). And LDPE is used most often in shrink wrap applications (at 192 million pounds).

Data compiled by Modern Plastics show that a total of 1,074 million pounds of polyethylene film were used in “other” packaging applications in 2015. (Again, data are not available for nonpolyethylene resins or for HDPE.) As piechart number 3 shows, LLDPE is used most often in stretch wrap applications (at 802 million pounds). And LDPE is used most often in shrink wrap applications (at 192 million pounds).

Non-packaging Applications

Of course, a great deal of film also is found in a category the industry refers to as nonpackaging applications. For example, it is commonly used to produce grocery, T-shirt and trash bags; can liners; agricultural film (such as greenhouse, fumigation and mulch films, haysleeve covers and silage bags); construction film (such as vapor barriers in walls, moisture barriers under concrete, paint drop cloths and drapes); medical and health care film (such as garbage and hazardous material bags, I.V. bags and sterile wrap); garment bags; self-service bags; household wrap; and as a component of disposable diapers.

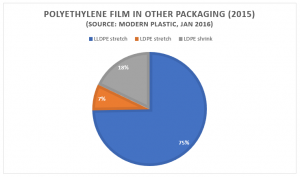

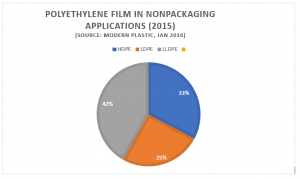

According to figures from Modern Plastics, approximately 3,730 million pounds of polyethylene film were used in nonpackaging applications in 2015. Pie chart number 4 shows how that film was distributed by polyethylene resin type.

It is important to remember that the figures presented in this section focus only on polyethylene films. Because data are collected in this manner only for members of the polyethylene family. That does not mean, however, that only polyethylene is used in these applications. For example, in the nonpackaging category PP films are used in such things as diapers and in the packaging category, polyester and polypropylene films are used in sterilization wrap.