General

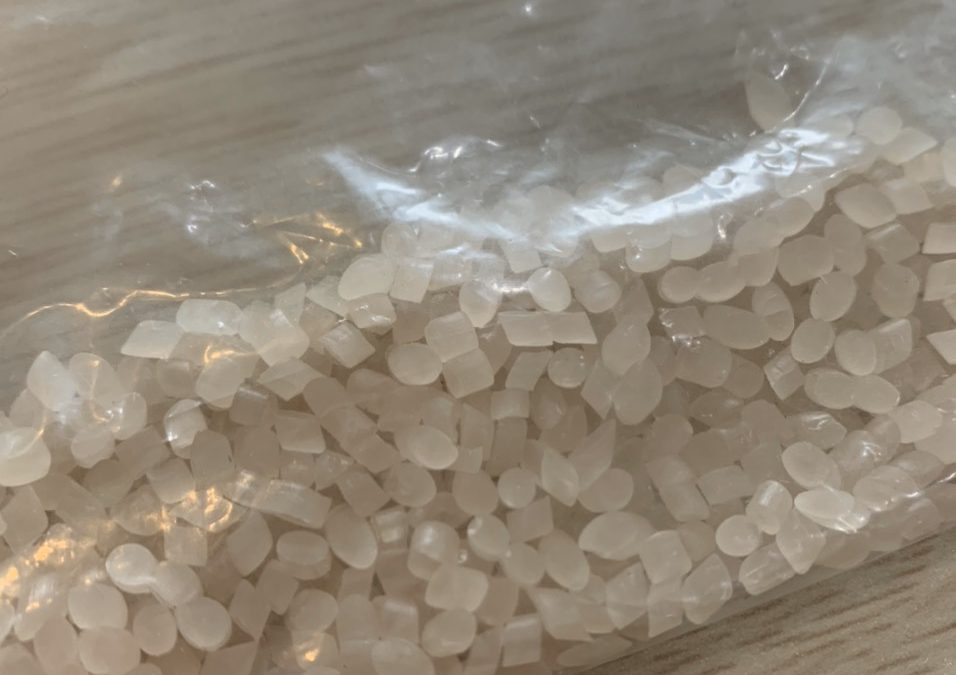

PBAT (short for polybutylene adipate terephthalate) is a biodegradable random copolymer, specifically a copolyester of adipic acid, 1,4-butanediol and terephthalic acid (from dimethyl terephthalate). PBAT is produced by many different manufacturers and may be known by the brand names ecoflex®, Wango, Ecoworld, Eastar Bio, and Origo-Bi. It is also called poly(butylene adipate-co-terephthalate) and sometimes polybutyrate-adipate-terephthalate (a misnomer) or even just “polybutyrate”.

It is generally marketed as a fully biodegradable alternative to low-density polyethylene, having many similar properties including flexibility. And resilience, allowing it to be used for many similar uses such as plastic bags and wraps. The structure of the PBAT polymer is shown to the right. It is depicted as a block co-polymer here. Due to the common synthetic method of first synthesizing two copolymer blocks and then combining them. However, it is important to note that the actual structure of the polymer is a random co-polymer of the blocks shown.

Production of plastics for use in the industrial sector around the world makes up a very large market. PET (polyethylene terephthalate) is one of the dominant plastics within this market. It is commonly used for bottles because it makes a rigid container that is very lightweight. However, because of the stability of PET, it is also highly resistant to biodegradation, posing a significant environmental problem. Because of the amount of PET produced, sold, used and thrown away on a daily basis. An estimated 30% of the world production of PET goes into making these plastic bottles and only from 15% to 35% ends up being recycled; the rest usually end up in a landfill. This has stimulated research into polymers that function comparably to PET, but are biodegradable.

More

As with all developments in the realm of materials there are several requirements for the ‘ideal’ material. For biodegradable plastics, they would be: cheap, renewable, easy to produce and eco-friendly. In addition to these, the polymer should be resistant enough to be functional, such as handling the strain of being put under pressurize, and flexible so that it is easy to mold. There are no polymers that perfectly provide every one of these features. Therefore, researchers have turned their attention to copolymers: combinations of polymers that have chemical and mechanical properties that complement each other. This led to identifying poly(butylene adipate-co-terephthalate) (PBAT) as a potential copolymer for blending.

PBAT is a random copolymer known for being flexible and tough. This makes it ideal for combination with other biodegradable polymers that have high elastic modulus and strength, but are very brittle. This allows for the production of blended copolymers that can replace industry-standard plastics with environmentally safe. And biodegradable plastics that will harmlessly disappear in a short period of time.

The most important reason of FILLPLAS for using PBAT as the flexible complement to other polymers is that it will preserve biodegradability; as long as both copolymers can degrade, the blended copolymer will also degrade.