General

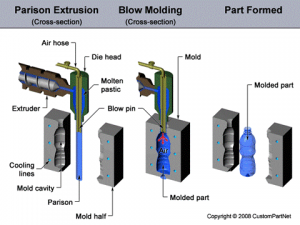

Blow molding is a manufacturing process that is used to create hollow plastic parts by inflating a heated plastic tube until it fills a mold and forms the desired shape. The raw material in this process is a thermoplastic in the form of small pellets or granules. Which is first melted and formed into a hollow tube, called the parison. There are various ways of forming the parison, as explained below. The parison clamped between two mold halves and inflated by pressurized air until it conforms to the inner shape of the mold cavity. Typical pressures are 25 to 150 psi, far less than for injection molding. Lastly, after the part has cooled, the mold halves separate and the part ejecte.

Classification

Parts made from blow molding are plastic, hollow, and thin-walled, such as bottles and containers that are available in a variety of shapes and sizes. Small products may include bottles for water, liquid soap, shampoo, motor oil, and milk, while larger containers. Which include plastic drums, tubs, and storage tanks. Blow molded parts can form from a variety of thermoplastic materials, including the following:

- Low Density Polyethylene (LDPE)

- High Density Polyethylene (HDPE)

- Polyethylene Terephtalate (PET)

- Polypropylene (PP)

- Polyvinyl Chloride (PVC)

As mentioning above, there are different methods using to form the parison which distinguish the following three forms of blow molding:

Extrusion blow molding

An extruder uses a rotating screw to force the molten plastic through a die head that forms the parison around a blow pin. The parison extrude vertically between the two open mold halves, so they can close on the parison and blow pin. Pressurized air flows through the blow pin to inflate the parison. This is the most common type of blow molding and use to manufacture large quantities of relatively simple parts.

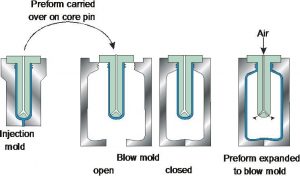

Injection blow molding

Injection blow molding

The molten plastic is injection molded around a core inside a parison mold to form the hollow parison. When the parison mold opens, both the parison and core transfer to the blow mold and securely clamped. The core then opens and allows pressurized air to inflate the parison. This is the least commonly using method because of the lower production rate, but is capable of forming more complicated parts with higher accuracy. Injection blow molding often prefer for small, complex bottles, such as those in medical applications.

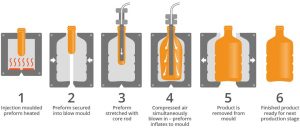

Stretch blow molding

The parison is formed in the same way as injection blow molding. However, once transferred to the blow mold, it heat and stretch downward by the core before being inflated. This stretching provides greater strength to the plastic. Stretch blow molding typically use to create parts that must withstand some internal pressure. Also be very durable, such as soda bottles.